Umgca weMveliso weStamping oshushu okhawulezayo we-ultral high-Strength Steel (Aluminiyam)

Ezona mpawu

Umgca wemveliso wenzelwe ukunyusa inkqubo yokwenziwa kwezixhobo zemoto ngokusetyenziswa kobuchwepheshe bokubetha okushushu. Le nkqubo, eyaziwa ngokuba yi-hot stamping e-Asiya kunye nokuqina koxinzelelo eYurophu, ibandakanya ukufudumeza izinto ezingenanto kwiqondo lobushushu elithile kwaye emva koko uyicinezele kwimold ehambelanayo usebenzisa itekhnoloji yokushicilela nge-hydraulic ngelixa ugcina uxinzelelo lokufikelela kwimo efunekayo kwaye ungene kwinguqu yesigaba semathiriyeli yentsimbi. Ubuchule besitampu obushushu bunokwahlulwa ngokweendlela ezithe ngqo kunye nezingathanga ngqo zesitampu esishushu.

Iingenelo

Enye yeenzuzo eziphambili zamacandelo olwakhiwo olunesitampu esishushu kukwakheka kwawo okugqwesileyo, okuvumela ukuveliswa kweejiyometri ezintsonkothileyo ezinamandla angaqhelekanga. Amandla aphezulu amacandelo ashushu anesitampu avumela ukusetyenziswa kwamaphepha esinyithi amancinci, ukunciphisa ubunzima bamacandelo ngelixa kugcinwa ukunyaniseka kwesakhiwo kunye nokusebenza kokuphahlazeka. Olunye uncedo lubandakanya:

UkuNcitshiswa kokuDityaniswa kweMisebenzi:Itekhnoloji yesitampu eshushu iyanciphisa imfuno ye-welding okanye yokuqinisa uqhagamshelo, okukhokelela ekuphuculweni kokusebenza kunye nokuphucula imfezeko yemveliso.

I-Springback eNcitshisiweyo kunye neWarpage:Inkqubo yesitampu eshushu inciphisa ukuguqulwa okungafunekiyo, okufana nenxalenye ye-springback kunye ne-warpage, iqinisekisa ukuchaneka okuchanekileyo kunye nokunciphisa isidingo sokuphinda kusetyenzwe kwakhona.

Iziphene ezimbalwa:Amalungu anesitampu esishushu abonisa iziphene ezimbalwa, ezifana nokuqhekeka kunye nokwahlula, xa kuthelekiswa neendlela zokubumba ezibandayo, ezikhokelela kumgangatho ophuculweyo wemveliso kunye nokunciphisa inkunkuma.

Ithoni yoCinizela ezantsi:Isitampu esishushu sinciphisa iitoni zokushicilela ezifunekayo xa kuthelekiswa neendlela zokubumba ezibandayo, okukhokelela ekugcinweni kweendleko kunye nokwandisa ukusebenza kakuhle kwemveliso.

ULungiso lweePropati zeMathiriyeli:Itekhnoloji yesitampu eshushu ivumela ukwenziwa ngokwezifiso kweempawu zezinto ezisekelwe kwiindawo ezithile zenxalenye, ukuphucula ukusebenza kunye nokusebenza.

UPhuculo lweMicrostructural eyomeleziweyo:Isitampu esishushu sinikezela ngesakhono sokuphucula i-microstructure yemathiriyeli, ekhokelela kukuphuculwa kweempawu zoomatshini kunye nokwanda kokuqina kwemveliso.

Amanyathelo eMveliso aLungelweyo:Isitampu esishushu siphelisa okanye sinciphisa amanyathelo okuvelisa aphakathi, okukhokelela kwinkqubo yokuvelisa eyenziwe lula, imveliso eyandisiweyo, kunye namaxesha amafutshane okukhokela.

Izicelo zeMveliso

I-High-Strength Steel (i-Aluminiyam) i-High-Speed Hot Stamping Production Line ifumana ukusetyenziswa okubanzi ekuveliseni amacandelo omzimba omhlophe wemoto. Oku kuquka iindibano zeentsika, iibhampa, imiqadi yeengcango, neendibano zophahla lukaloliwe ezisetyenziswa kwizithuthi zabakhweli. Ukongeza, ukusetyenziswa kwe-alloys ephucukileyo enikwe amandla yisitampu esishushu kuphononongwa ngakumbi kumashishini anje nge-aerospace, ukhuselo, kunye neemarike ezivelayo. Ezi alloys zinika inzuzo yamandla aphezulu kunye nokunciphisa ubunzima obunzima ukufezekisa ngokusebenzisa ezinye iindlela zokwenza.

Ukuqukumbela, i-High-Strength Steel (i-Aluminium) i-Speed-Speed Hot Stamping Production Line iqinisekisa ukuveliswa okuchanekileyo kunye nokusebenza kakuhle kwamalungu omzimba wemoto. Ngokwakheka okuphezulu, imisebenzi yokudibanisa encitshisiweyo, iziphene ezincitshisiweyo, kunye neempawu zezinto eziphathekayo eziphuculweyo, lo mgca wemveliso ubonelela ngeenzuzo ezininzi. Usetyenziso lwayo lunabela ekwenziweni kwamalungu omzimba amhlophe kwizithuthi zabakhweli kwaye ibonelela ngeenzuzo ezinokubakho kwi-aerospace, ukukhusela kunye neemarike ezivelayo. Tyala imali kwi-High-Sight-Strength Steel (i-Aluminium) i-High-Speed Hot Stamping Production Line ukufezekisa ukusebenza okugqwesileyo, imveliso, kunye nenzuzo yoyilo olukhaphukhaphu kwiimoto kunye namashishini ahlangeneyo.

Yintoni isitampu esishushu?

Isitampu esishushu, esikwabizwa ngokuba kukuqina koxinzelelo eYurophu kunye nokwenza ucinezelo olushushu e-Asia, yindlela yokwenza izinto apho indawo engenanto ifudunyezwa kubushushu obuthile kwaye emva koko igximfizwe kwaye icinywe phantsi koxinzelelo kwifa elihambelanayo ukuze kuphunyezwe imilo efunekayo kwaye kuphembelele ukuguqulwa kwesigaba kwizinto zentsimbi. Itekhnoloji eshushu yokunyathela ibandakanya ukufudumeza amashiti entsimbi ye-boron (ngamandla okuqala e-500-700 MPa) ukuya kwimeko ye-austenitizing, ngokukhawuleza ukuwadlulisela ekufeni ngenxa yokunyathela ngesantya esiphezulu, kunye nokucima inxalenye ngaphakathi kwi-die kwizinga lokupholisa elingaphezu kwe-27 ° C / s, lilandelwa lixesha lokubamba phantsi koxinzelelo, ukufumana isakhiwo se-ultra-high-high-high-high-steel.

Iinzuzo zokunyathela ezishushu

Ukuphuculwa kokugqibela kokuqina kunye nokukwazi ukwenza iijiyometri ezinzima.

Ukunciphisa ubunzima becandelo ngokusebenzisa i-sheet sheet encinci ngelixa ugcina imfezeko yesakhiwo kunye nokusebenza kokuphazamiseka.

Ukuncipha kwesidingo sokujoyina imisebenzi efana ne-welding okanye ukuqina.

Inxalenye encitshisiweyo iphuma emva kwaye iwarping.

Iziphene ezincinci ezinje ngokuqhekeka kunye nokuqhekeka.

Iimfuno zoxinzelelo lwetoni ezisezantsi xa kuthelekiswa nokubumba okubandayo.

Ukukwazi ukulungelelanisa iipropathi zezinto ezisekelwe kwiindawo ezithile zeenxalenye.

Ukomelezwa kwe-microstructures yokusebenza ngcono.

Inkqubo yokwenziwa lula kunye namanyathelo ambalwa okusebenza ukufumana imveliso egqityiweyo.

Ezi nzuzo zinegalelo ekusebenzeni kakuhle ngokubanzi, umgangatho, kunye nokusebenza kwamacandelo esakhiwo esinesitampu esishushu.

Iinkcukacha ezithe vetshe malunga nesitampu esishushu

1.Isitampu esishushu vs

I-Hot stamping yinkqubo yokuqulunqa eyenziwa emva kokutshisa ishidi lentsimbi, ngelixa i-stamping ebandayo ibhekisela kwisitampu esithe ngqo seshiti lentsimbi ngaphandle kokushisa.

Isitampu esibandayo sineengenelo ezicacileyo ngaphezu kokunyathela okushushu. Nangona kunjalo, ikwabonisa ezinye izinto ezingeloncedo. Ngenxa yoxinzelelo oluphezulu olubangelwa yinkqubo yesitampu ebandayo xa kuthelekiswa nesitampu esishushu, iimveliso ezinesitampu ezibandayo zisengozini yokuqhekeka kunye nokwahlula. Ke ngoko, izixhobo ezichanekileyo zokutywina ziyafuneka ukuze kufakwe isitampu esibandayo.

Isitampu esishushu sibandakanya ukufudumeza ishidi lentsimbi ukuya kumaqondo obushushu aphezulu ngaphambi kokuba ugximfize kwaye kwangaxeshanye ucime kwifa. Oku kukhokelela ekuguqulweni okupheleleyo kwe-microstructure yensimbi ibe yi-martensite, okubangelwa amandla aphezulu ukusuka kwi-1500 ukuya kwi-2000 MPa. Ngenxa yoko, iimveliso ezinesitampu ezishushu zibonisa amandla aphezulu xa kuthelekiswa noogxa ababandayo.

2.Hot Stamping Process

Isitampu esishushu, esikwabizwa ngokuba yi "press hardening," ibandakanya ukufudumeza ishidi elinamandla aphezulu ngamandla okuqala angama-500-600 MPa kumaqondo obushushu aphakathi kwe-880 kunye ne-950 ° C. Iphepha elivuthayo lifakwe ngokukhawuleza kwaye licinywe kwi-die, lifezekisa amazinga okupholisa ama-20-300 ° C / s. Ukuguqulwa kwe-austenite ibe yi-martensite ngexesha lokucima ngokubonakalayo kwandisa amandla ecandelo, ukuvumela ukuveliswa kweendawo ezinesitampu ezinamandla ukuya kuthi ga kwi-1500 MPa.Iendlela zokunyathela ezishushu zingahlelwa zibe ziindidi ezimbini: isitampu esishushu esithe ngqo kunye nesitampu esishushu esingathanga ngqo:

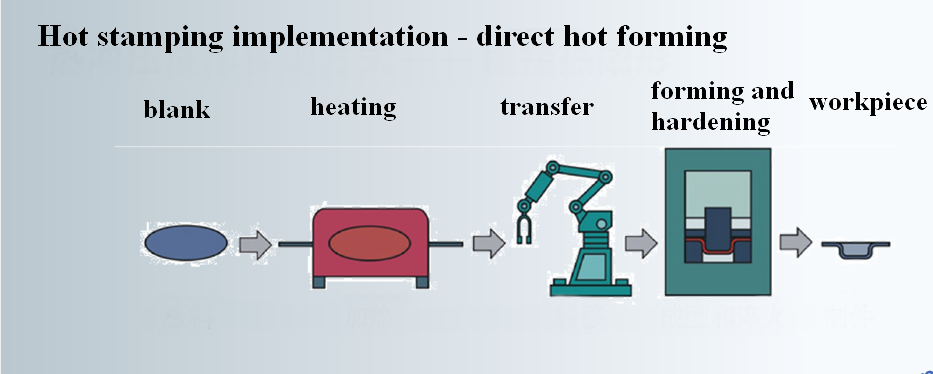

Kwi-stamping eshushu ethe ngqo, i-preheated blank ifakwe ngokuthe ngqo kwi-die evaliweyo yokunyathela kunye nokucima. Iinkqubo ezilandelayo ziquka ukupholisa, ukunqunyulwa komphetho kunye nokubetha umngxuma (okanye ukusika i-laser), kunye nokucoca indawo.

I-Fiture1: imowudi yokucoca isitampu esishushu--isitampu esishushu ngqo

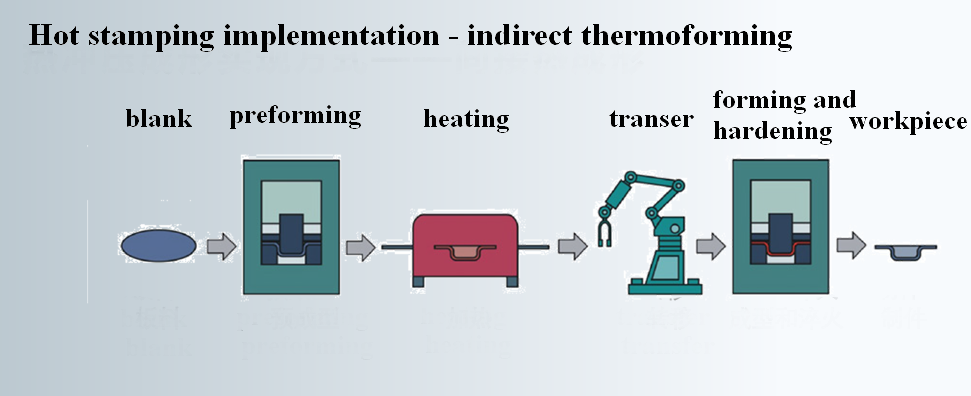

Kwinkqubo ye-stamping eshushu engathanga ngqo, inyathelo elibandayo lokubumba i-pre-shaping inyathelo lenziwa ngaphambi kokungena kwizigaba zokufudumeza, ukunyathela okushushu, ukusika umphetho, ukubethelwa komngxuma, kunye nokucoca umphezulu.

Umahluko ophambili phakathi kwe-stamping eshushu engathanga ngqo kunye neenkqubo ze-stamping ezishushu ngokuthe ngqo zilele ekufakweni kwesinyathelo esibandayo esenza i-pre-shaping step ngaphambi kokufudumeza kwindlela engathanga ngqo. Kwi-stamping eshushu ngokuthe ngqo, i-sheet metal ifakwe ngokuthe ngqo kwisithando sokufudumala, ngelixa i-stamping eshushu engathanga ngqo, icandelo elibandayo elibunjwe ngaphambili lithunyelwa kwisithando somlilo.

Inkqubo yokuhamba kwesitampu esishushu esingathanga ngqo ibandakanya la manyathelo alandelayo:

Ukubumba okubandayo kwangaphambili--Ukufudumala-Isitampu esishushu--Ukucheba komphetho kunye nokugqobhoza komngxuma-Ukucoca umphezulu

I-Fiture2: imowudi yokuqhubela phambili isitampu esishushu--isitampu esishushu esingathanga ngqo

3.Esona sixhobo siphambili sokubetha isitampu esishushu sibandakanya iziko lokufudumeza, umatshini wokushicilela oshushu, kunye nokubumba okushushu.

Iziko lokufudumeza:

Isithando somlilo sixhotyiswe ngokufudumeza kunye namandla okulawula ubushushu. Iyakwazi ukufudumeza iiplati zamandla aphezulu kwiqondo lokushisa elihlaziyiweyo ngaphakathi kwexesha elithile, ukufezekisa i-austenitic state. Kufuneka ikwazi ukuziqhelanisa neemfuneko ezinkulu zemveliso ezizenzekelayo eziqhubekayo. Njengoko i-billet evuthayo inokuphathwa kuphela ngamarobhothi okanye iingalo zomatshini, isithando somlilo sifuna ukulayishwa ngokuzenzekelayo kunye nokukhulula ngokuchaneka kokubeka okuphezulu. Ukongezelela, xa ufudumeza iipleyiti zetsimbi ezingafakwanga, kufuneka zinikeze ukukhuselwa kwegesi ukukhusela i-oxidation yomhlaba kunye ne-decarbonization ye-billet.

I-Hot Forming Press:

Umshicileli ngundoqo weteknoloji yokunyathela eshushu. Kufuneka ikwazi ukunyathela ngokukhawuleza kunye nokubamba, kunye nokuxhotyiswa ngenkqubo yokupholisa ngokukhawuleza. Ubugocigoci bobugcisa bomatshini bokwenza oomatshini bokwenza ishushu bubodlula lee obo bomatshini bokushicilela ababandayo abaqhelekileyo. Sithetha nje, zimbalwa iinkampani zamazwe angaphandle eziye zakwazi ukuyila nokuvelisa ubugcisa bohlobo lokushicilela, yaye zonke zixhomekeke ekuthengeni impahla evela kwamanye amazwe, nto leyo ebenza babize kakhulu.

Ukungunda okushushu:

Ukubumba okutshisayo kokubumba kwenza zombini izigaba zokubumba kunye nokucima. Kwinqanaba lokubumba, emva kokuba i-billet ifakwe kwi-mold cavity, i-mold igqiba ngokukhawuleza inkqubo yesitampu ukuqinisekisa ukugqitywa kokwakheka kwenxalenye ngaphambi kokuba izinto ziqhube ukuguqulwa kwesigaba se-martensitic. Emva koko, ingena kwinqanaba lokucima kunye nokupholisa, apho ukushisa okuvela kwi-workpiece ngaphakathi kwesikhunta ngokuqhubekayo kudluliselwe kwi-mold. Imibhobho yokupholisa elungiselelwe ngaphakathi kokungunda isusa ngoko nangoko ubushushu kwisisipholisi esihambayo. Utshintsho lwe-martensitic-austenitic luqala xa ubushushu besixhobo sokusebenza sehla ukuya kuma-425°C. Utshintsho phakathi kwe-martensite kunye ne-austenite iphela xa iqondo lokushisa lifikelela kuma-280 ° C, kwaye i-workpiece ikhutshwe kwi-200 ° C. Indima yokubamba i-mold kukuthintela ukwanda kwe-thermal kunye nokunciphisa ukungalingani ngexesha lenkqubo yokucima, okunokubangela utshintsho olubalulekileyo kwimilo kunye nobukhulu becala, okukhokelela kwi-scrap. Ukongeza, iphucula ukusebenza kakuhle kokuhanjiswa kwe-thermal phakathi kwendawo yokusebenza kunye nokungunda, ikhuthaza ukucima ngokukhawuleza kunye nokupholisa.

Isishwankathelo, izixhobo eziphambili zesitampu esishushu zibandakanya isithando somlilo sokufezekisa ubushushu obufunwayo, umshicileli oshushu wokwenza isitampu ngokukhawuleza kwaye ubambe ngenkqubo yokupholisa ngokukhawuleza, kunye nokubumba okutshisa okutshisayo okwenza zombini izigaba zokubumba kunye nokucima ukuze kuqinisekiswe ukubunjwa kwenxalenye efanelekileyo kunye nokupholisa ngokufanelekileyo.

Ukucima isantya sokupholisa akuchaphazeli kuphela ixesha lokuvelisa, kodwa kuchaphazela nokusebenza kokuguqulwa phakathi kwe-austenite kunye ne-martensite. Isantya sokupholisa sinquma ukuba luhlobo luni lwesakhiwo sekristalline esiza kwenziwa kwaye sihambelana nomphumo wokugqibela wokuqina komsebenzi. Ubushushu obubalulekileyo bokupholisa bentsimbi ye-boron bumalunga ne-30 ℃/s, kwaye kuphela xa izinga lokupholisa lidlula iqondo lokupholisa elibalulekileyo apho ukubunjwa kwesakhiwo se-martensitic kunokukhuthazwa ukuya kwinqanaba elikhulu. Xa izinga lokupholisa lingaphantsi kweqondo lokupholisa elibalulekileyo, izakhiwo ezingezizo ze-martensitic ezifana ne-bainite ziya kubonakala kwi-workpiece crystallization structure. Nangona kunjalo, ukuphakama kweqondo lokupholisa, kungcono, ukuphakama kwesantya sokupholisa kuya kukhokelela ekuqhekekeni kwamalungu abunjiweyo, kwaye uluhlu lwezinga lokupholisa olufanelekileyo lufuna ukuqinisekiswa ngokubunjwa kwezinto kunye neemeko zenkqubo yamacandelo.

Ekubeni uyilo lombhobho wokupholisa luhambelana ngokuthe ngqo nobukhulu besantya sokupholisa, umbhobho wokupholisa ngokuqhelekileyo uyilwe ukusuka kumbono weyona ndlela iphezulu yokufudumeza ubushushu, ngoko ke isalathiso sombhobho wokupholisa ocetyiweyo sinzima ngakumbi, kwaye kunzima ukufumana ngokugrumba ngoomatshini emva kokugqitywa kokubunjwa kokubumba. Ukuze ugweme ukuthintelwa ngokucutshungulwa komatshini, indlela yokugcina imijelo yamanzi phambi kokuba i-mold casting ikhethwe ngokubanzi.

Ngenxa yokuba isebenza ixesha elide kwi-200 ℃ ukuya kwi-880 ~ 950 ℃ phantsi kweemeko ezibandayo kunye nezishushu ezitshintshanayo, izinto ezitshisayo zokufa kwestamping kufuneka zibe nobungqongqo obulungileyo kunye nokuhanjiswa kwe-thermal, kwaye zinokuxhathisa i-friction eyomeleleyo ye-thermal eveliswa yi-billet kwiqondo lokushisa eliphezulu kunye ne-abrasive wear oxide ye-particle ehlayo. Ukongeza, izinto zokubumba kufuneka zibe nokuxhathisa okulungileyo kokuhlwa kwisipholisi ukuqinisekisa ukuhamba kakuhle kombhobho wokupholisa.

Ukucheba nokugqobhoza

Ngenxa yokuba amandla amacandelo emva kokunyathela okutshisayo afikelela malunga ne-1500MPa, ukuba ukusika kunye nokubethelwa kwe-press kusetyenziswa, iimfuno zezixhobo ze-tonnage zinkulu, kwaye i-die cutting edge inxiba inzima. Ke ngoko, iiyunithi zokusika i-laser zihlala zisetyenziselwa ukusika imiphetho kunye nemingxuma.

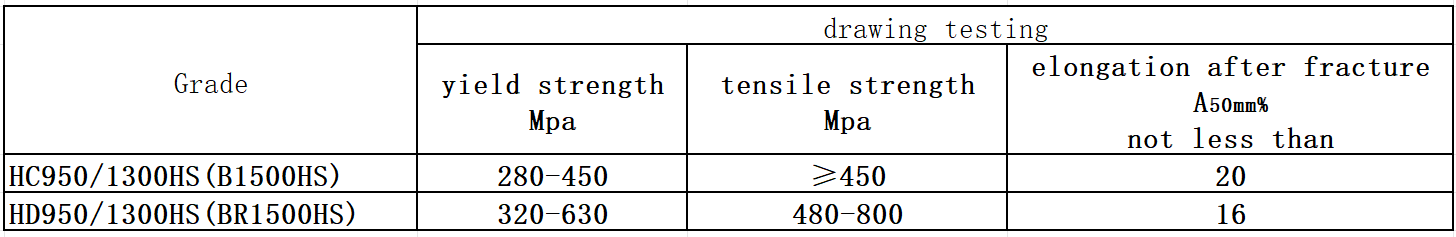

4.Amabakala aqhelekileyo entsimbi yokunyathela eshushu

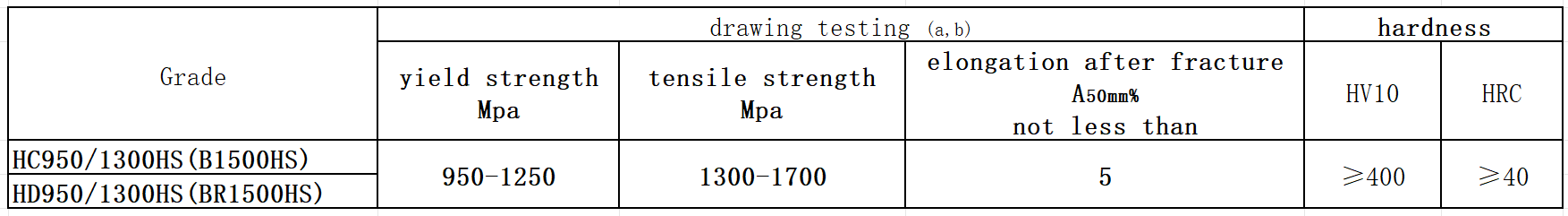

Ukusebenza ngaphambi kokufakwa kwesitampu

Ukusebenza emva kwesitampu

Okwangoku, ibakala eliqhelekileyo lentsimbi yesitampu eshushu yi-B1500HS. Amandla okuqina ngaphambi kokuba kufakwe isitampu ngokubanzi phakathi kwe-480-800MPa, kwaye emva kwesitampu, amandla okuqina anokufikelela kwi-1300-1700MPa. Oko kukuthi, amandla okuqina e-480-800MPa yentsimbi yepleyiti, ngokusebenzisa isitampu esishushu sokwenza, anokufumana amandla okuqina amalunga ne-1300-1700MPa.

5.Ukusetyenziswa kwentsimbi yesitampu eshushu

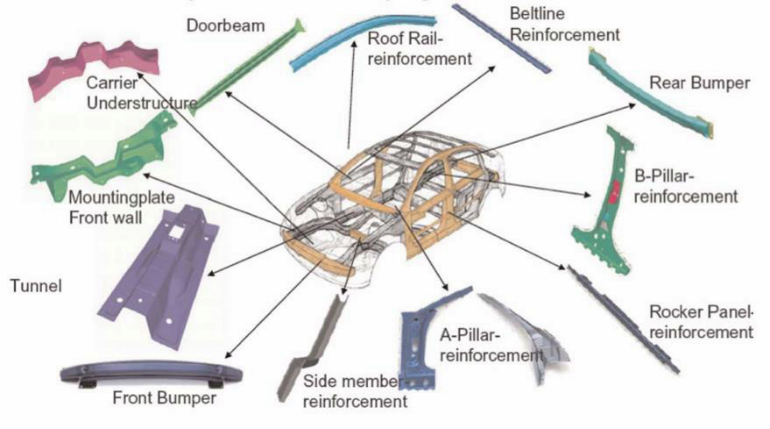

Ukusetyenziswa kweendawo ezishushu zokutsibela kunokuphucula kakhulu ukhuseleko lokungqubana kwemoto kwaye uqonde ubulula bomzimba wemoto ngombala omhlophe. Okwangoku, iteknoloji ye-stamping eshushu isetyenziswe kumalungu omzimba omhlophe weemoto zabagibeli, njengemoto, intsika, intsika ye-B, i-bumper, i-door beam kunye ne-roof rail kunye nezinye iindawo.Jonga umzobo 3 apha ngezantsi umzekelo iindawo ezifanelekileyo zokulinganisa ukukhanya.

umzobo 3: Amalungu omzimba amhlophe alungele isitampu esishushu

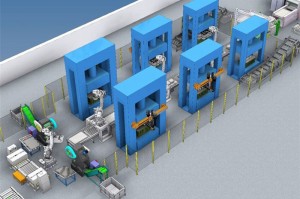

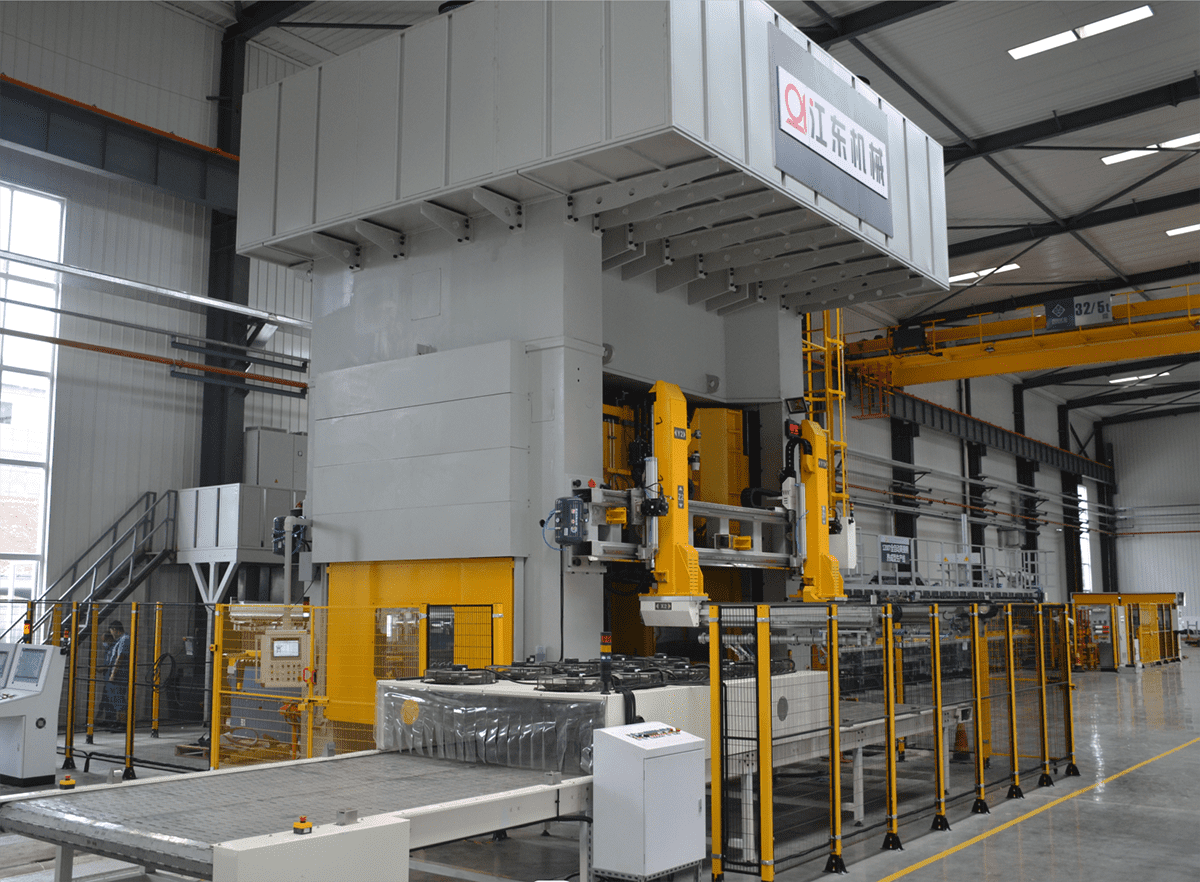

Umzobo 4: jiangdong oomatshini 1200 Ton Hot Stamping Press Line

Okwangoku, i-JIANGDONG MACHINERY eshushu yokunyathela izisombululo zomgca wokuvelisa i-hydraulic ivuthiwe kwaye izinzile, kwintsimi yaseTshayina eshushu yokwenza isitampu ikwinqanaba eliphambili, kwaye njengoko iChina Machine Tool Association ibumba umatshini wesebe usekela-sihlalo weyunithi kunye neeyunithi zamalungu eChina Forging Machinery Standardization Committee, siye saphinda saqhuba uphando kunye nesicelo sophando oluphezulu kunye nesicelo sentsimbi yesizwe i-aluminiyam, edlale indima enkulu ekukhuthazeni uphuhliso loshishino lwesitampu olushushu eTshayina nakwihlabathi liphela.